A General View of the Coal Trade of Scotland Chiefly that of the River Forth and Midlothian.

To which is added an inquiry into the condition of the women who carry coals underground in Scotland, known by the name of bearers.

By Robert Bald, Alloa, Civil Engineer and Mineral Surveyor; Member of the Wernerian Natural History Society of Edinburgh, and Honorary Member of the Geological Society of London, 1812

Alloa, August 14,1808.

Preface

The following short Treatise relative to the Coal-trade of Scotland, is with much diffidence presented to the Public.

I am sensible, that the style in which it is written, is far from that kind of composition which is expected from those whose writings are to meet the public eye: but the avocations of a laborious life will, it is hoped, be admitted at least as some extenuation* if not an excuse*

I trust, however, that the statements which are adduced will be found correct, at least sufficiently so for a general view of the subject, without entering into very minute calculations.

Having been engaged from an early period of life in the operations of collieries, many of the statements are made from personal knowledge of the subject.

The authorities which I have consulted upon the occasion are,

1. Records of the Family of Mar, in particular a collection of papers connected with the Coal-Trade, left by John Earl of Mar, now in the possession of John Francis Erskine of Mar, Esq;

2. Brand's History of Newcastle.

3. Encyclopaedia Britannica.

4. Statistical Account of Scotland, by Sir John Sinclair.

After the Work was sent to the Press, I was favoured with the perusal of a Tract, published by Lord Dundonald in the year 1793, (which is not now to be found in the booksellers' shops), in which I was much gratified to find, that his Lordship had discussed several of the points 1 have treated of; in particular, the bad system pursued in the Forth Collieries, of separating the coals into Great-coal, Chews, Lime-coal, and Panwood, - the alteration of which system is one of the principal improvements suggested in the following Treatise, and to which I beg leave to solicit particular attention. His Lordship also takes notice of the slavery endured by the women who carry coals underground.

I shall be happy, if what I have stated in the following sheets shall meet the public approbation, and shall tend to produce any improvements in the Scottish Coal-Trade, for the interest of all concerned.

R. B.

CONTENTS.

CHAP. I - Preliminary Observations. - Price of Coals in Edinburgh and Glasgow. - State in which Collieries were a Century ago

CHAP. II. - Price of Coals, and the amount of Colliers' and Labourers Wages, a Century ago. - Invention of the Steam Engine, - and its Effects. - Great Rise in the Price of Coals since the year 1785. - Remarks upon the Value of Coal Fields, and upon the Capitals employed in Collieries

CHAP. III. - Inquiry into the Causes which occasion the great difference in the price of Coals in Edinburgh and Glasgow. - Detail of the Modes of Working Coal at Glasgow, and in the River Forth District. - Present average prices of Coals

CHAP. IV. - Of the using of Coals in Private Houses and Public Works. - The adopting of the Glasgow mode of Working and of Selling Coals recommended

CHAP. V. - The importance of the Coal Mines to Great Britain, considered in a National and Political point of View

CHAP. VI. - Limited number of Colliers in Scotland considered. - Their numbers cannot be increased, as in other Trades. - Investigation of the Cause. - Loss sustained by the State, when Colliers become Soldiers or common Labourers.- Value of a Collier’s Work in an agricultural point of View

CHAP. VII. - Inquiry into the expediency of Exporting Coals to the Continent. - Rapid progress of the Coal-Trade in the Eighteenth Century. - The prominent Improvements. - Sketch of the Boundaries of the Main Coal-Field of Scotland. - The Improvement of our Country depends upon the Collieries. - Ideas of Philosophers respecting the renovation of the Coal fields

CHAP. VIII.

Hints to Philosophers and Men of Science for aiding the Labours of the Practical Mineralogist. - A standard Nomenclature much wanted. - Plan humbly proposed for correcting this great impediment to the Science of Mineralogy

Inquiry into the Condition of those Women who carry Coals under Ground in Scotland, known by the name of Bearers

APPENDIX.

No. 1. License granted in the year 1725 by the Inventors of the Steam-Engine, to Andrew Wauchope of Edmonstone, Esq

No. 2. Account of the Expence of the Edmonstone Steam-Engine

No. 3. Contract betwixt the Engineers who erected the Edmonstone Engine, relative to the improving of a Steam-Engine, and directing the operation of one of the Edmonstone Collieries

No. 4. Review of the Coal-Trade, since the Year 1808

No. V. Statement regarding an Investigation made lately by Government, in order to obtain a Minute Account of the Output and Sales of Coal in each Colliery, with the view of Imposing an Excise Duty on Coal

CHAP. I. - Preliminary Observations. - Price of Coals in Edinburgh and Glasgow. - State in which Collieries were a Century ago.

In the list of articles of household expenditure in Scotland, that of Fuel bears a considerable proportion in the monthly expences of a family; and in our cold, damp, and variable climate, during winter, the comfort of a good cheerful fire is indispensably requisite to our health, independently of its use in culinary purposes, and those trades, upon a small scale, where a certain degree of heat is so very necessary.

The using of Peat as fuel is daily decreasing, as the spirit of agriculture spreads; the husbandman, now finding by experience, that it is more for his interest to buy Coals at a very high price, than waste his time and labour in digging peat, as that time and labour come to much better account, when expended in improving his farm.

Pit-coal is therefore every day coming more and more into use; and its intrinsic value to Britain, in a civil and political point of view, is so obvious, as almost to preclude the bringing forward any illustrations upon these heads. Observations have been made by able and well informed men upon this subject; but as the writer has now, for a number of years, been closely engaged in the operations of collieries in Scotland, he begs leave to contribute his share of information upon so important a matter.

The occasion of the following remarks upon the Coal Trade, arose from the great advance which has taken place in the price of coals in Edinburgh within these few years; an advance of at least cent. per cent.,- which bears hard on the middling classes of society, but more severely upon mechanics, labourers, and the lower orders of the community.

That the price of coals is advanced, is what might have been naturally expected from the great increase of the price of labour, and of all materials used at collieries; while, at the same time, it is certain, that the coalmasters have by no means reaped that advantage, which is generally believed they have done, from these advances.

One circumstance respecting the price of coals in Edinburgh, is very remarkable; and it is surprising that no person, fully acquainted with all the facts connected with it, has made a thorough investigation of the matter; and it is this, - that the inhabitants of Glasgow have coals delivered at their houses at about one-half of the price paid by the inhabitants of Edinburgh; that is, they are in Glasgow 7 d., in Edinburgh they are i s. per cwt., and the Glasgow coals are allowed to be fully equal in quality, if not superior, to those in the vicinity of Edinburgh.

Before inquiring into the cause of this great difference in price, we shall take a review of the Coal Trade in Scotland, particularly from the beginning of last century, from which some very curious facts will appear, respecting the price of coals in the river Forth, as connected with the supplying of fuel to the capital, and North of Scotland.

The first authentic accounts we have of coal being wrought in Scotland, was in the lands belonging to the Abbey of Dunfermline, in the year 1291,—a period not very remote.

The collieries then opened were drained of their water by mines or levels brought up from low ground, until they intersected the bed of coal.

The coal fields thus drained, adjoining the river Forth, being very limited, recourse was had to water machinery, and the first account we have of these machines, is in the year 1600, when a patent was granted for twenty-one years, to a predecessor of the Balcarras family, for his invention of a machine for drawing water from collieries.

A short time after this, the collieries at Culross in Perthshire appear to have been the most extensive then in Scotland, as an act was passed in the year 1663, 1st Charles II., chap. 17., constituting the Culross chalder of coals the standard for Scotland. From the profits of these collieries the Abbey of Culross is said to have been built.

We find, that in the year 1690, waterwheels were commonly employed, having a large axle across the pit mouth, over which was an endless chain of two or three tires reaching to the coal; to these were attached a number of oblong wooden buckets or troughs, in an horizontal direction, which were continually filling at the bottom and discharging at the top, as they turned over the great axletree. When there was abundance of water for the wheel, the full complement of buckets was placed upon the chains, but as the water decreased, a proportional number of buckets was taken off, which was the only plan for regulating this rude machine.

Although each bucket was full of water as it was lifted from the pit-bottom, none of them were more than half full at the discharging point near the axletree, owing to the leakage of the joints, and vibrations of the chains, so that the water was constantly pouring down the pit like a deluge.

The keeping of this machine in repair was very expensive. The chains for a pit of eighty yards deep cost then L. 160; and, when a bolt gave way, the whole set of chains and buckets fell to the bottom with the most tremendous crash, and every bucket was splintered to a thousand pieces.

It was for these machines that many of the large artificial collections of water we now have in coal districts were formed, and that at a very great expence.

When water could not be procured, the same kind of machinery was used upon a small scale, moved with horses, which was comparatively very expensive, and could only draw water from a small depth; of course, all those fine fields of coal, where neither a day level nor water machinery could be employed, had to remain useless to their owner and the public, and that to all appearance for ever, as there was no other device for getting clear of the water.

In the year 1708, when a plan was projected in Scotland, for drawing water from coal mines, by means of wind-mills and pumps, it appears that there was no person in Scotland capable of giving advice upon the matter, or of executing the work, except the mill-wright of Montrose , who had been sent at the expence of that town to Holland, in order to inspect the machinery of that country. Of this circumstance, the town of Montrose has reason to be proud. And it was suggested, that if this mill-wright could not be procured, application should be made to the Mechanical Priest in Lancashire for his advice.

Wind-mills were accordingly erected upon several collieries, but although they were powerful machines, they were very irregular, so that in a long tract of calm weather, the mines were drowned, and all the workmen thrown idle. From this cause, the contingent expences of these machines were very great; besides, they were only applicable in open and elevated situations.

In the year 1709, John Earl of Mar, who not only paid the most minute attention to the improvements of his collieries in Clackmananshire, but also studied the general improvement of Scotland on a great and extensive scale, with the most liberal views, sent the manager of his works to Newcastle, to inspect the machinery of that district, and learn the mode of conducting colliery-operations in every department.

From his report, it appears, that the machines then in use were water-wheels, and horse-engines, with chain-pumps; the common depth of the pits was from twenty to thirty fathoms, and a few from fifty to sixty fathoms: the expence for sinking one of these was about L. 55, and the machine for drawing the coals cost only L. 28.

It appears, that when it was requisite to draw water from the depth of thirty fathoms, two pits were sunk at a little distance from each other; one pit was made thirty fathoms deep, the other only half that depth. One machine drew the water half way up the deep pit, when it was poured into a mine which communicated with the bottom of the other pit; from this the water was raised to the surface by another machine. In deeper mines, a third pit with a third machine was resorted to.

In Scotland, however at that time, the machinery was more powerful, as water was raised at once from the depth of forty fathoms by the chain and bucket, as before described.

Barlow's machine is also taken notice of, as being in use at Newcastle; but the steam-engine is not even hinted at.

The colliery which was then upon the greatest scale at Newcastle, put out annually 25,000 chalders of coals, and made of clear profit L. 5000 per annum, a great amount, when compared with the present value of money. The collieries then going were few in number: at present, no less than sixty-six names of great collieries stand upon the lists at the Coal Exchange, London.

At that time, waggon-ways were in use at Newcastle; but they were not introduced into Scotland till a considerable time afterwards.

The Earl of Mar having procured drawings of the Newcastle machinery, wished to introduce such parts of it as he conceived might be useful in his works; for this purpose, he, in the year following, viz. in 1710, engaged an engineer from Derby, in the county of Derby, to visit and inspect his collieries in Clackmananshire, and to give plans for improving the machinery, particularly for drawing water, which was the great object in view with all coalmasters. The specified sum which the engineer was to have for his trouble was L.50 Sterling money; and he accordingly came to Alloa, where he remained for some days, and left a report, and his opinion of what he conceived best to be done. Among other things, he advised the substituting of pumps in place of chains and buckets. But when he went away, still there could be found no person in Scotland to put his plans in execution. The chain and bucket engine was, however, superseded by the water-wheel with cranks and beams working with pumps. This machine is the most simple of all the hydraulic engines, and from the simplicity of construction, it remains in common use to the present day. It is so easily kept in repair that any colliery which is drained by it, is nearly upon a footing with a level free colliery.

Attempts have been made to improve this machine, but the results have not been very favourable.

The sinking of pits in Scotland at this period, was the most tedious and severe work that can be imagined; the sinking of an engine-pit requiring several years for its accomplishment, as the beds of strong hard sandstone are much thicker and more abundant than in the English coal field. Gunpowder was not then used in sinking; for although it seems to have been applied to this purpose in England, about the year 1680, it was not in common use for many years afterwards; and it is indeed astonishing to think how it was contrived to sink pits through strata, upon which we find, that the best tempered steel pick can make no impression. The mode then practised in sinking through hard strata, was by a set of tools termed stook and coil, or stook and feathers. The manner of application was as follows:

In the first place, a bore-hole of from two to three inches diameter, was put down several feet, by means of a steel auger; two long slips of iron named the feathers, were placed down each side of the hole, and betwixt these a long tapering wedge, termed the stook, was inserted; this wedge was driven down with ponderous hammers, till the rock was wrenched asunder. This was a powerful instrument, but its operation was very slow and expensive. We have had no opportunity of seeing this mode in practice. The above account is taken from the tradition of old colliers and sinkers, who report, that the progress made in sinking through hard stone was so very slow, that the coalmaster frequently inquired if the sinkers were lything the water, that is, making it of a thick and muddy colour by their operations.

This difficulty of sinking pits was the occasion of the coal being wrought far under the dip of the engine-pits, which was effected by either damming and laving, or by sloping pumps. From this mode of working, many disasters occur to the present collieries, by coming upon old wastes full of water, where it was conceived no wastes could be, thus endangering the mens' lives, and drowning the colliery.

These facts are stated to shew, that collieries, both in England and Scotland, were only in their infancy exactly one hundred years ago, which is an important point to be kept in view.

The colliery operations upon the crop or verge of the coal, were uniformly continued until there was no cover of rock above the coal, and the consequence was, that the earth sunk down along the whole stretch of the workings, and admitted vast quantities of water to the mines every rainy season, over and above the common and natural growth of the strata, and which to this day remain an almost overpowering load upon many of the best coalfields, where the most powerful machinery is at present employed to keep the mines dry, and this water will continue to occasion an excessive expence on such works while they exist; for instance, there is one very valuable colliery, where the growth of water arising from the above cause, requires a machine capable of bringing from the depth of 270 feet, no less than one million of gallons every twenty-four hours.

From the causes above stated, the collieries then at work were few in number, and a strong demand for coals in England; and it is certain, that much more money was then made in Scotland by working coal, than has been made these last thirty years, even with all our additional knowledge and experience in coal-mining, aided with highly-improved and powerful machinery.

CHAP. II. - Price of Coals, and the amount of Colliers and Labourers Wages, a Century ago. - Invention of the Steam Engine, - and its Effects. - Great Rise in the Price of Coals since the year 1785. - Remarks upon the Value of Coal Fields, and upon the Capitals employed in Collieries.

With respect to the price of coal a century ago, we find, that about that period, particularly in the year 1715, great coal was put free on board in the river Forth, at 4 s. 8 d. per ton, when the labourer's wages were at 6 d. per day, and all materials used at collieries cheap in proportion; the wages of a miner or sinker were 10 d. per day; and as colliers' wages are generally rather more than double that of a common labourer, we may estimate their winnings at 14d. per day. It is therefore conceived, that the price of labour is a fair criterion by which we may estimate the comparative price of coals.

In this way collieries were carried on, and confined in a very few hands, until the happy invention of the Steam-Engine,—an invention of the highest utility to Britain, and without which we would have been very far behind in our most important mining and commercial concerns.

It appears, that the steam-engine was first applied to collieries upon Newcomen's principle, upon which principle it still continues in general use, on account of its simplicity. The great improvements by subsequent engineers, and particularly by the ingenious and celebrated Mr Watt, has rendered this machine the most complete and powerful of any that philosophy and the genius of man have presented to the world.

Newcomen obtained his patent in the year 1705, and the engine was brought forward for collieries in the year 1712. Between this time and the year 1720, they began to be commonly used at Newcastle.

But in what place the first of these engines was erected in Scotland, we have not been able to learn with precision, even after making every inquiry upon the subject; and it is rather surprising to think, that the first erection of a machine of such consequence is not a matter of notoriety.

In consulting the Statistical Accounts of Scotland, we find, that the steam-engine erected at Elphingstone, in the county of Stirling, and parish of Airth, is stated to be the second of the kind put up in Scotland. Understanding that a steam-engine had been erected at an early period at Edmonstone Colliery, in the county of Mid-Lothian, an application was made by a gentleman to the present proprietor, John Wauchope, Esq; inquiring if he could throw any light on this subject.

Mr Wauchope instantly attended to the application, and, in a very polite manner, sent from the family records those papers which still remained relative to the erecting of the steam-engine at Edmonstone Colliery. They are authentic documents, and I therefore feel much indebted to that gentleman for his liberal communications, and still more so for his granting me permission to take what notice of these papers I thought proper.

The first of these papers is dated May 1725. It is "A license granted by the Committee in London, appointed and authorised by the Proprietors of the Invention for raising Water by Fire, to Andrew Wauchope of Edmonstone, Esquire."

This license states, that as the colliery at Edmonstone could not be wrought by reason of water, liberty is granted to erect one engine, with a steam cylinder nine feet long, and twenty-eight inches diameter, according to the method and manner now used at the coalwork of Elphingstone in Scotland; for which license a royalty of L. 80 per annum was to be paid for eight years.

As this deed contains a great many clauses, conditions and reservations, a copy of it is annexed in the Appendix, No. 1. and also a copy of the discharge for the royalty at the expiry of the term of years.

The second of these papers contains an account of the expence of the materials of this machine, exclusive of the engine-house, the amount of which is L. 1007 : 11 : 4. This account contains every minute article furnished; it is a curious and valuable paper, dated 1727. It is likewise inserted in the Appendix, No. 2. and is deserving of particular notice.

From the reference made in the license, we are inclined to suppose, that the Elphingstone steam-engine, in the county of Stirling, was the first of that kind erected in Scotland. This must have taken place about the year 1720, which is corroborated by the traditions of the old colliers.

It is evident from these papers, that the erecting of a steam-engine was a most arduous and expensive undertaking, and all those men employed in the execution of the work were sent from England.

The steam-cylinder, some of the working barrels, and all the buckets and clacks, were made of brass, somewhere beyond London. The common pumps for the pit were of elm, of a bore nine inches diameter, and made out of the solid tree, hooped with iron, and brought from London. The boiler top was made of lead; it is presumed that this was used on account of the supposition, that plates of iron, rivetted together, could not be made sufficiently tight to contain steam.

The cost of this engine was very great; for, if compared with the present value of money, it may be stated at L. 4000. This great expence evidently arose from the quantity of brass employed. The substituting of cast-metal, and the great improvements which have been made in the foundry department, have comparatively reduced the cost of these machines very much; so much so, that the materials for an engine upon Newcomen's principles, and of the size of the Edmonstone engine, with a complete pile of cast-iron pumps, can at present be furnished for a sum not much exceeding the half of the sum paid for the Edmonstone machine. This is one of the many advantages we have gained by industry and a close application to the improvement of our machinery.

From the discharge granted for the royalty, it appears, that the sum of L. 240 was paid in full of all demands, whereas the sum specified in the license was L. 640.

But, as it is natural to suppose, that the machine would at first be very imperfect, and frequently going wrong, an abatement of the royalty might be made on that account, according to an express stipulation in the license. At the same time, it must be remarked, that however imperfect and awkward we may suppose this machine to have been, it was the foundation of the greatest improvements in machinery which have appeared in the kingdom.

That these engines were very little understood, and very difficult to be kept in order, appears from an agreement entered into betwixt the tacksman of one of Mr Wauchope's collieries, and the engineers who erected the steam-engine. It is there stipulated, that the engineers were to have no less a sum than L. 200 a-year to keep the engine going, and were, besides, to have the half of the clear profits of the colliery, after paying all expences.

It was also stipulated, that if the engineers could not make the engine draw water, so as to place the colliery in working order, they were to have liberty of taking away all the materials furnished by them, and to be paid a reasonable allowance for their pains and charges.

This shews, that there was but little confidence as to the result, after expending great labour and expences in erecting steam-engines at that period.

A copy of this contract is given in the Appendix, No. 3. and it is hoped that the copy of these documents will be acceptable to those who are interested in the coal fields of Scotland.

Although at this instant, the Glasgow Collieries are very numerous and extensive, yet it appears, that the steam-engine was not introduced there until the year 1763, which is another strong proof of the rapid progress which collieries have made since that date, in every department of the business.

The steam-engine produced a new era in the mining and commercial interests of Britain, and as it were in an instant put every coal field, which was considered as lost, within the grasp of its owner. Collieries were opened in every, district, and such has been the astonishing effect produced by this machine, that great coal was shipping free on board, in the river Forth, in the year 1785, at 4 s. 10 d. per ton, that is, after a period of seventy years, coals had only advanced 2 d. per ton, while the price of labour, and all materials, was doubled. This is so striking, that it seems scarce credible, had not the statement been taken from most authentic documents.

It is to the steam-engine alone we owe this very great advantage, and surely those men deserve well of their country, who have, by their genius and industry, contributed so much to its most essential interests.

The great competition in the coal-trade, which has continued since the above period, has evidently enabled Britain to bring her manufactures to market, and undersell all other competitors, even in those countries where the price of labour was not one-third of what was paid at home.

With respect to the profits of the coalmasters, they are said to have been very great about a century ago; but it is certain, that since the introduction of the steam-engine, few or no fortunes have been made in this line in Scotland; indeed, it is commonly asserted, that upon the whole, there has been more loss than gain. We have not access to know what the profits precisely have been of late, but there is every reason to conclude, that very little has been cleared per ton upon the annual sales, and that it is so near the losing point, as scarcely to be an object worthy of pursuit. Still, however, the general idea is, that the profits yielded by Scotch collieries are great. In England, however, there are strong examples to the contrary, and princely fortunes have been acquired. No doubt, there are collieries in Scotland that make handsome returns, but they are but few in number.

The short period of the last twenty-two years has produced a great advance upon the price of coals shipped on the river Forth; for, from the year 1785 to the year 1800, they rose from 4s. 10d. to 7s. per ton. At this instant they are from 9s. to 11s. per ton, (great coal always being understood); but during this latter period, the price of labour has again been doubled, and the price of wood, iron and ropes, much advanced.

As the price of labour appears to be a proper scale to compare the price of coals by, let us consider what ought to have been the cost of a ton of coals at present, compared with the price of last century. Labourers' wages were then 6d.; colliers is. 2d.; four times the colliers' wages was the price of the ton, viz. 4s. 8d. The present rate of labourers' wages may be rated at 2s. per day; that of a collier at 4s. 6d. Four times this sum is 18s., and this appears to be the sum per ton for which coals ought to have been sold at present, in order to have produced a return to the coalmaster, master, equal to the returns made from coal a century ago; and the price would have been even higher, had not the steam-engine been applied to drain the water from collieries.

There is one view of a colliery which has seldom been taken into account and considered, which is this: In any estate, the number of acres of coal is limited; each year a certain proportion of the whole is wrought and sold, and, as to the owner, completely alienated. In other commercial concerns, the same ground can be gone over again and again, and by one generation after another; but a coal-field once wrought out, ceases for ever. If, therefore, the coalmaster cannot bring his acres of coal to good account, it would be better that they never had been brought to light, at least in so far as regards him.

But the bold and public spirit of adventure is such, and the enterprising mind of man so aptive, that the hope of better years keeps always plenty of coal in the market; a circumstance most fortunate and well ordered for the community. And indeed those concerned in collieries would require to receive something like an adequate return in the adventure; for, excepting war, and the sea, we know of no other business attended with such excessive labour and anxiety in every department, or where men are so frequently brought to their wits end, and called upon to run every risk of life, limb, and fortune.

With respect to the capitals employed in collieries, they are great, for which 5 per cent. is no equivalent; and if we suppose, for example, that L.20,000 is laid out upon a colliery, this stock would not bring L.4000, if the colliery was given up. This is one of the strong inducements which makes coalmasters carry on collieries, even under the most unfavourable circumstances; for, while a colliery is at work, all the estimated stock is really and absolutely of the full value as it stands; but the instant the concern stops, the stock surfers the full diminution above stated.

CHAP. III. - Inquiry into the Causes which occasion the great difference in the price of Coals in Edinburgh and Glasgow. - Detail of the Modes of Working Coal at Glasgow, and in the River Forth District. - Present average prices of Coals.

Let us now inquire into the causes of the vast disproportion between the prices of coals at Edinburgh and Glasgow.

The collieries which chiefly supply Edinburgh with coals by land-carriage, are situated, at an average, about five and a half miles distant; the distance to the nearest being about four miles, to the farthest about seven miles. No city in the kingdom is more fortunately situated, not only in respect of distance, but also in respect of the extent of coal-field, the thickness and number of seams.

Those which supply Glasgow, are situated about four miles distant; the nearest being about two miles, the farthest about five miles from the city. We must, therefore, in point of distance, allow a proportion of price corresponding thereto.

The price of coals upon the coal-hills round Edinburgh, is 11 s. 8 d. per ton; at Glasgow, it is, on an average, 8 s. 4 d. 3 -from this we must calculate for whatever difference there may be in the working of the coal: it does not interfere with this statement.

The common hire which an Edinburgh carter makes, upon an average, per day, with one horse, is about 5 s.; a Glasgow carter will not work, unless he can be assured of making from 9 s. to 12 s.

The difference is great beyond all proportion, and more than compensates for the difference of distance to the collieries. There must, therefore, either be some great fault here, or the Edinburgh carter has other means of subsisting than the mere hire.

The business of carting the coals to Edinburgh, appears to be done in the very worst style. The carts are badly constructed, and frequently not five inches deep in the sides, which are made of four rough pieces of wood fixed with pins at each corner, where it would not be easy to place a heavy load. The condition of the horses accords somewhat with the construction of the cart, and many of them cost from L. 3 to L. 4 only: the general weight brought to the city, is 12 cwt., and if 15 cwt. is at times brought, it is the highest. To distilleries and public works, where economy is attended to, the carters very willingly take a ton weight, or even 24 cwt. which at least serves to shew what may be done.

At Glasgow we see a different order of things; the cart is of excellent construction, the horses are strong, well fed, and cost from L. 30 to L. 50 each. The common weight carried, is 24 cwt., and that in constant practice. Is it not remarkable to observe so great a difference in doing the same kind of work in the two greatest cities of Scotland, considering how short a distance there is between them?

One cause of the great difference of the carter's hire, arises from the superior mode in which the coal sales are conducted at Glasgow. There each colliery has an agent in the city, who receives orders for coals ; these orders are sent out each day to the respective collieries, by which means, the manager appoints each carter his day's work before he leaves the colliery in the morning. By this plan, the delivery of the coals is quite regular; no time is lost; all imposition is avoided, as the carter has nothing to do with the money for the coals, but is answerable for the weight delivered. This last is of much importance; for, without this, it is hard to say what the price of the coals is. The city of Edinburgh has had much to do attempting to correct the great abuses in this alone ; and this point has not yet been effectually adjusted.

The system pursued by the Edinburgh carters is very different indeed, which not only operates against the inhabitants, but against themselves.

When the coals are in great request, and no stock of them upon the hills, they go in crowds to the different collieries, and wait very long ere they are served ; frequently lose a whole day; each cart of coals is weighed by 4 cwt. at a time upon a common beam; this is the practice of the best collieries, by which much time is lost: the introduction of weighing-machines, as practised at Glasgow, would be a great improvement. When the demand becomes less, the coals are procured sooner at the hills; but as they frequently have no orders for coals in the city, it is no uncommon thing for them to lose a day standing in the streets before they get a merchant; and from this view of the matter, it is wonderful how they contrive to keep themselves and horses alive, even with all their industry and skill.

The common work of a Glasgow coal carter each day, is to go twelve miles with his cart loaded with 24 cwt. of coals, and return the same distance with it empty. The average distance from the city to the collieries is about four miles, as before stated, so that he loads and empties his cart three times; and for carrying the above weight four miles, he gains 3 s. 6 d. The result is, that a ton is carried one mile for 8 1/4 d.

The common average work of an Edinburgh coal-carter each day, is to go either four or seven miles, according to the distance of the respective collieries, loaded with 12 cwt. of coals, and return the same distance empty. The average distance from the city to the collieries is about five and a half miles, so that he loads and empties his cart once; and for carrying the above weight, he gains about 4 s. 9 d. The result is, that a ton is carried one mile for 1 s. 5 d, being a difference in his favour, compared with the Glasgow carter, of no less than 9 d. per ton, or nearly cent, per cent. Even at this very great advance of price, he is not near so well off as the Glasgow carter, and the citizens of Edinburgh pay high for this bad system.

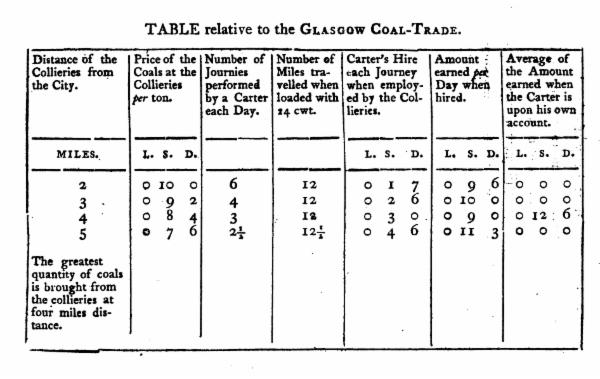

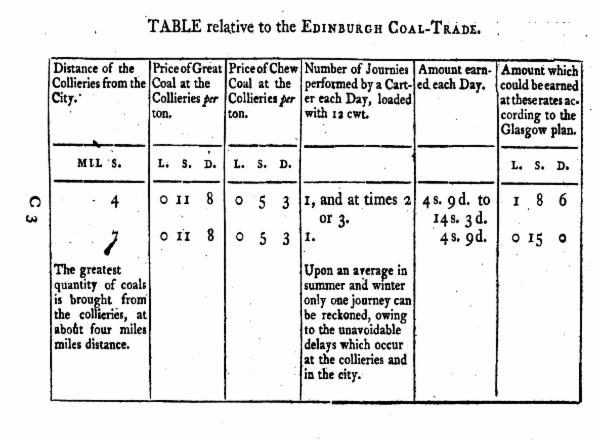

From the great irregularity of this mode of conducting the work, it is not easy to give such accurate statements as could be wished; but the following tables will shew more precisely the great superiority of the Glasgow system over that of Edinburgh.

From the Table of the Glasgow coal-trade, it appears, that the prices of coals are at the collieries in proportion to their distance from the market,—a natural consequence in almost every branch of trade; and the work performed is also in the same proportion, only the amount of a day's work as to length of journey is the same, and the earnings are high.

Whereas from the Table of the Edinburgh coal-trade, it appears, that the prices of coals are the same at all the collieries, whatever be the disproportion in point of distance; and this most evidently arises from the very bad and ruinous system, .pursued; in short, the errors here are so very glaring and obvious, that it is not necessary to make further comments upon a subject where a reformation is so much wanted. The coals at the Edinburgh collieries are not dearer than at the Glasgow collieries, when we consider that the latter are mixed coals. The extra expence arises from the system upon which the collieries are wrought, the carting, and bad mode of conducting the sales. Even high as the cartage is, the carters are not so well off by one-half as their neighbours at Glasgow.

As the chews at the Edinburgh hills are no less than 50 per cent, cheaper than the great coal, it is certain, that if the Glasgow system were wholly adopted, the Edinburgh coalmasters could afford to sell their coals as cheap as the coalmasters at Glasgow, and with greater profit than by the present plan pursued.

The supply of coal which Edinburgh receives by sea is chiefly from the collieries of Halbeath, St David's, and Wemyss, upon the opposite coast, or from those up the river, the farthest of which is Alloa, distant about twenty-four miles. These collieries ship their great coal on board, after a carriage of from one to five miles, at the rate of ten or eleven shillings per ton. The freight to Leith, and carriage from thence to Edinburgh, fluctuate according to the demand; but the average freight in summer and winter may be stated at four shillings per ton for great coal: the freights of chews are always lower, on account of a cargo of them being got sooner at the coal port than great coal.

Within these few years, the plan of the coal-trade carried on by sea to Leith and the North of Scotland has changed considerably.

Formerly the shipmaster was the merchant, and he waited at the port where he was selling his coals, frequently for many weeks, when sales were dull, at times disposing of only a ton or two each day. This plan was attended with not only great loss of time, but also with very great expence.

The trade is now very much into the hands of merchants, who live at the port or coal market, and pay a certain freight per ton to the shipmaster. By this means there is no detention at the market, so that the shipmaster instantly returns to the collieries for another cargo. In this way he gains less money each voyage; but, on the other hand, he can make more voyages in a given time.

Upon the whole, one would think, that this mode of conducting the trade is in favour of the community at large, provided it continues a free and open trade to every one who may choose to try it. These coals can be afforded at the prices current in Edinburgh, even with all this additional expence.

Besides this supply from the collieries on the river Forth, a very great quantity of English coal is daily brought to market, of which last there are different qualities and prices at Newcastle and Sunderland; and it is evident, that if this extra supply of Scotch and English coals had not come to market, the price of coals in Edinburgh, and in the North of Scotland, must have far exceeded the present prices, high as they are thought to be.

In the buying and selling of coals, as in other merchandise, there is a diversity of weight and measures, which gives rise to the greatest abuses.

At the country collieries, coals are sold by the load, the mett, the cart, by a certain number of stones Dutch, or by the hundred weight; the consequence is, that excepting a person buys by the latter, he cannot know what he is about.

At market, they are sold by the waggon, ton, cart, hundred weight, dale, boll, creel, stone and chalder; and when we speak of a chalder, it is as difficult to find out what the quantity is as any of the rest; because

The London chalder is - 27 cwt.

The river Forth chalder, - 30 do.

The Newcastle chalder, about - 52 do.

The Perth chalder, nearly 5 tons,

and every other district of country has its own peculiar weights and measures.

This kingdom has long complained of these grievances, which are much felt, but without redress, and we are told, that the great nicety of adjusting a physical standard is the cause of the delay. France has shewed us a good example in this particular. If the principles there assumed are correct, might they not be adopted? One universal weight and measure would correct many errors, and give a greater facility to mercantile transactions.

We now come to state another most evident cause, which enhances the price of coal to the inhabitants of Edinburgh, above those of Glasgow. This arises from a strong and deep-rooted prejudice, and although the remedy is cleat as noon-day, it will in all probability be neglected, until higher prices urge the necessity of attending to it.

What is here alluded to is this,—an idea is formed by the inhabitants of Edinburgh, that the coal which is in large masses is of a quality far superior to that which is of a small size, commonly termed chews, (dross or culm being out of the question, as it will not easily burn in a common fire-place.) This prejudice is not peculiar to Edinburgh, it is equally prevalent in Dundee, Perth, Dunbar, and all those towns which are supplied with coals from the river Forth.

With respect to the quality of great coal and chews, it is the same; for, in general, a bed or seam of coal, as it lies under the various strata, is of pretty uniform hardness, excepting those bands of splint coal, which occur less or more in almost every seam. And the art of the collier is to hew down immense blocks of coal, in size from one to four cubic yards at a time. In this operation, a quantity of dross or culm is produced in every colliery. The next step, is to divide this block into pieces, in order that they may be transported to the hill. This operation, and the subsequent handling of them, uniformly produces chews and culm. Coals that are termed Chews, are in size from a cubic inch, to that of five inches on the side. From this is it not evident, that chows are of the identical quality of great coal, being only great coal broken down?

Chews are at present shipped in the river Forth, at from 7 s. to 8 s. per ton, and are chiefly used in glass-works, foundries, breweries, air-furnaces, and lime-works; and when free of culm, they produce a heat much more intense than if large masses of coal were used, on account of their presenting a much larger burning surface to the air, and producing a reciprocal action of heat among the different pieces.

The term Great Coal, being unknown in the Glasgow and Ayrshire collieries, we must now state the labour and difficulties which the prejudice before mentioned produces in the coal-trade, and shew how the inhabitants of Edinburgh, and the North of Scotland suffer by it.

In the Glasgow collieries, when the collier has brought down from the wall a mass of coal, he, with a sharp pick, divides it into pieces, the largest of which a man can easily lift ;- a quantity of chews and culm is produced, as before mentioned. The chews and culm are first thrown into the basket which carries the coal to the hill, and the round coals are built firmly above them. In this manner they are drawn to the pit-bottom by horses or men, and from thence sent up to the hill, tor sale, where only two kinds of coal are known, viz. Coals and Dross.

When, therefore, a cart is to be filled with these coals, the round coals are laid aside, and a labourer, with a riddle of an inch mesh, separates the dross from the small cubic pieces of coal. Those coals which keep above the riddle, are thrown into the cart, and the quantity of this kind is regulated by the general quantity of small coal which the seam yields in working, which in practice is easily ascertained. The round coals are put on next, and built in a very firm manner above the mouth of the cart, a mode in which the Glasgow carters are very dexterous. The weight of the cart having been previously ascertained, the weight of the coals are adjusted on a steelyard, by the hill-grieve, and thus delivered to the consumer.

This is the whole process of the Glasgow system. The dross which is separated, is sold for the use of steam-engines, so universally used for driving machinery; it suits the purpose very well, and is afforded at 20 d. per ton on the hill.

In this way the coalmaster brings all his coal to market, excepting what must be left in pillars to support the superincumbent strata. To the collier all is reckoned productive labour, excepting the dross, and the consumer has the coals of such a size as best suits him, and upon moderate terms, so that all the parties, are satisfied.

The mixed coal is not only used in Glasgow, but also in Paisley, Port-Glasgow, Greenock, and all the towns upon the west coast without exception. And the Ayrshire coals, which chiefly go to the Dublin market, are precisely of the same kind, and are of course put on board of ship with great facility, in comparison of the labour requisite in shipping great coal, which, with the filling of the waggon, costs not less than 7 d. per ton on the river Forth.

In East Lothian, the coals are wrought also upon the Glasgow plan.

The plan pursued in working coals upon the river. Forth, is very different.

When the collier has got the mass of coal brought down from the wall, he with the greatest possible care separates it into pieces which are as heavy as one or two men can with difficulty lift, and it is his object to have them as near this standard as possible. If the coal be free and soft, he is as careful of 'breaking it into small coal or chews as if he were handling plates of glass. There is, however, a quantity of small coal and chews produced, beside what arose from the first operation. The great coal is laid up on one side of the mine, the chews on the other, and the lime coal and panwood are most commonly thrown aside into the waste, and lost for ever; and what is more surprising, about twenty years ago many thousand tons of chows were also every year thrown aside, because no person would buy them, on account of the imagined inferiority; and it required all the attention and perseverance of the most skilful coalmasters, to introduce them into our manufactures, where they are now preferred, and solely used.

When the coal is ready to be sent to the pit bottom, if women are employed as bearers, immense loads are put upon their backs, and these oppressed females, groaning under heavy burdens, travel to the pit, where they lay down the coals, and build them up in the place appointed for each collier, until their respective turn arrives for sending their coals to the hill. When a collier's turn arrives, he leaves his work at the wall-face, and rolls the pieces of coal to the volume of the pit, where, with great care and difficulty, they are put into the basket. Upon their arriving at the hill, they are laid down at the side of the bin, where they are again, piece by piece, built up like a wall; and in this operation chews and small coal are again produced and separated. The next step is to transport them to sea, when each piece of coal is carefully taken down from the bin, and built in the waggon in a horizontal position, to prevent breakage: here chews and small coal are again produced and separated. Upon the waggon arriving at the shipping place, the coals are either carried on handbarrows, or slid down a plank to the hatch of the vessel, where each piece of coal is built up in the hold, exactly in the same manner as bricks are placed, to prevent breakage. In this operation alone, seven men are required for each vessel which is loading. The chews and culm produced here are shipped along with the great coal.

Upon the ship arriving at the port or market, the coals are handed out, piece by piece, and put on the carts; an additional quantity of chews and small coal is again produced, and that in proportion to the softness of the coal. These small coals sell at a price far below the great coals, and occasion a dead loss to the shipmaster. The great coals are at last laid into the cellar, and the consumer estimates their quality exactly in proportion to their size; and well they may be valued, considering the great toil, trouble, and extra expence which is incurred for this great object! Let us now see the result of the whole business.

To burn such masses of coal as are in the cellars, is quite impossible, as they would not kindle by any ordinary means. If, therefore, in a winter morning, attention is paid to what is going on in the coal-cellar of each family, where a number of fires are to be put on, nothing is to be heard but hard blows; and upon entering, what must be the astonishment of those who have attended to the whole detail of keeping the coal in large masses, to see them at last violently attacked with every kind of destructive implement, such as heavy cannon-balls, double and single headed shot, hammers of all descriptions, axes, crows, pokers, picks, and pieces of whinstone, or by one piece of coal dashed with violence against the other; all with a view to reduce part of them to chews, which was previously so much avoided, and which could be bought 30 per cent. cheaper than the great coal. Of the above implements actually used for breaking coal, not one is adapted for the purpose except the pick: all the rest not only break the coal into chews, but absolutely bruise much of it into a powder of no use; and therefore, while the predilection for great coal continues, no family ought to allow their coals to be broken by any other implement than a light sharp pick.

It is probable, that some persons who may read the above statement, will ask in amazement, Is this really the case? It is a fact; and it may be seen in practice every day in Edinburgh, Leith, Dundee, Perth, and in all those towns which are supplied with coals from the river Forth, and no where else. Our west country friends are better economists in the coal-trade, from the wall face to the room grate.

From this demand for Great Coal in the market, no fewer than four kinds of coal are produced in every colliery, viz. Great Coal, Chews, Lime-coal, and Panwood or Dross, all of them from the same mass; so that even the dross contains, in a given weight, nearly as much of the true principles of coal as any of the other kinds .

The following statement shews precisely the result of the two modes of working the coalfield.

Glasgow System.

Left in pillars, 1/3

Coal wrought, 2/3

The wrought coal is thus divided:

Large coals diminishing to the size of three-fourths of an inch, 12/15

Dross or culm, used for engines, &c. 3/15

River Forth System.

Left in pillars, 1/3

Coal wrought, 2/3

The wrought coal is thus divided:

Great coal, 8/15

Chows, having lost in value 30 per cent 4/15

Lime, coal, and dross or culm, thrown aside and lost for ever. 3/15

From all that is above stated, is it not plain and evident, that the price of great coal is greatly enhanced from the extra labour attending it from the wall face, to its being put on the fire? The facility of the West country mode, and its superiority in every point of view, is obvious at a glance. The collier's work is comparatively easier ; he can work the ton at a much less price, and in short the whole detail is simple, economical and business like; whereas the Forth system is intricate, laborious, expensive, lavish as to the coal-field, and carries folly in its face. But such are the strong implanted prejudices, that it is probable the system will for a long time be persisted in, until the coals rise to such an extravagant price, that strong necessity alone will bring about a change.

Great coal is rapidly advancing in price, and must continue to do so; for even at this instant, the Glasgow coalmasters have as good prices for their mixed coal, as the Forth coalmasters have for their great coal.

The present prices of coals upon the coalhills in Scotland, are from 4 s. 2d. to 11s. 8 d. per ton. The prices paid the collier is from 1 s. 6 d. to 5 s. per ton. These prices shew the great difficulties which one colliery may labour under, when compared with another.

The average prices of coal at present put on board of ship, may be estimated as follows:

Great coal, L.0 10s 0d

Chews, L.0 7s 0d

Lime coal, L.0 4s 4d

Panwood or dross, L.0 3s 0d

The collier is paid for his work somewhat in proportion to the above, excepting for the dross, for which he receives nothing.

CHAP. IV. - Of the using of Coals in Private Houses and Public Works. The adopting of the Glasgow mode of Working and of Selling Coals recommended.

We now come to take a view of the using of coal, as connected with household economy and public works.

The price of coals on the river Forth was formerly stated, and we may, for precise calculation, state the great coal at 10 s., the chews at 7 s. per ton, being a difference of no less than 30 per cent. This shews in a strong light, how much the great coal must be loaded with an extra expence; for every time they are turned over, as before described, a portion of chews is produced; and each piece of great coal thus broke down loses exactly 30 per cent, of its value, independently of the dross, which will scarcely bring any money. This loss must, therefore, be added to the price of the great coal.

It will naturally be asked, Would not families find their account in burning chews in place of great coal, seeing they are so much cheaper? To which it must be observed, that the quantity of chews produced in any colliery, bears a certain limited proportion to the great coal, depending upon the quality of the seam ; that is, a Splint-coal will produce a less proportion of chews than a soft cubical coal, and therefore there could not be a sufficient supply of chews for the market; besides, being in small pieces not exceeding five pounds in weight, they blaze so rapidly away, that the extra quantity consumed, would be nearly equal to the extra expence of the great coal: for kitchen-fires, however, no kind of coal can he better adapted.

With respect to room-fires, the best economy is, to make a fire of chews in the morning to warm the house, and as it will be in full heat after breakfast, a large piece of coal should be placed on the centre of the fire, having the reed or fracture in an horizontal direction, with small coal packed around it. This fire will last a day, and keep the room at a proper degree of comfortable temperature; therefore, in an economical point of view, pieces of great coal are absolutely necessary.

From what has now been stated, is it not evident, that mixed coal, as used in Glasgow, is exactly what a family must have, and which the inhabitants of Edinburgh and the North of Scotland have the trouble of making from great coal, at a very high premium? If the inhabitants of Glasgow were to demand great coal from the collieries, no money would induce the coalmasters to introduce such an expensive and useless plan; because, in all operations, the great point in view is to render them as simple as possible, and this is attained most completely by the west country system.

Further, to shew that the predilection for great coal arises from habit and prejudice, there are many families living in Edinburgh at present, who formerly lived in Glasgow: they will all acknowledge, that the mixed coals they used in Glasgow, made as good fires as the great coal they at present use in Edinburgh, and in general very superior. Besides, there is a great supply of coals brought to Glasgow from the neighbourhood of Airdrie, by the Monkland Canal: these coals find a ready market in the city, and they undergo the same fatigue and breakage as mixed coals would do, if sent from any of the collieries, upon the river Forth, and landed at Leith, or the North of Scotland. Can any arguments be more in point?

With respect to the dross or culm which is always produced, it ought to be used a little wet, and put round the great coal; but it ought never to be put on any fire, excepting when the fuel is in full heat, otherwise it stifles the burning, and renders it the most uncomfortable fire that can be imagined, as the dross of Scotch coal, (with a few exceptions), will not cake in an ordinary fire like the rich English coals; and in families, the dross ought to be separated by a wire-riddle, of a quarter of an inch mesh. All the coal which keeps above, will, when thrown on a fire, produce a most excellent glow; so that there need be no loss of any part of the coals.

Another demand for large blocks of coals, is, for the servants to make what is termed gathering-coals in the kitchen; the largest pieces are carefully preserved for this purpose; so that upon looking into a kitchen about three o'clock in the morning, a strong fire will frequently be found, fit for roasting an ox.

This great fire is knocked to pieces in the morning, and simply serves the purpose of carrying fire to the other rooms of the house. This is not only an expensive mode, but highly dangerous, and very much destroys the furniture, by the flakes of soot which arise from the fires carrying through the house, over and above the burning of carpets.

In London, and in towns where the economy of fuel is particularly attended to, the kitchen fire is put out every night; and each family considers a quantity of fire-wood to be as necessary in a house as coal. The first work of a servant in the morning is to strike a light, and with the help of wood, a fire in the kitchen is instantly made; the room fires are put on with wood and coals, so that a redhot poker from the kitchen very soon kindles the whole.

This is a good and economical plan, and is at present practised by a few families in Scotland.

The next point in question is, if mixed coals were used, would they be cheaper? Certainly they would, as will evidently appear from the following statement.

It has been found by experience, that, in general, the chews produced in a colliery, bear the proportion of about one-third to the great coal. Therefore, at the present prices, and under the present system, if they were mixed together, the price per ton of mixed coal would be as follows:

Two Two tons great coal, at 10s. L.1 0s 0d

One ton chews, at 7 s. L.0 7s 0d

L.1 7s 0d

Which, divided by three, leaves 9 s. per ton for the mixed coal, or it is 10 per cent. cheaper.

As to the coal consumed in manufactories, chews are generally used at glasshouses, foundries, breweries, soapworks, and in all such furnaces; but as the quantity of this kind of coal is limited, great coal is frequently resorted to; and therefore, upon the whole, their expence would be very little increased, by burning mixed coal, as is practised in the manufactories in the west country. In distilleries supplied with coals from the river Forth, a strong prejudice has been formed against chew coal, and therefore great coal is uniformly used; so that a person upon entering a still-house, is surprised to see the large blocks of coal, shivered to a thousand pieces with a large hammer, and reduced precisely to chews before they be thrown into the furnace. And the reason is obvious; because this size of coal produces the most violent and rapid combustion.

The great objection to the use of chews, is, that there is in them a great mixture of culm, which, when put into the furnace, choaks the fire, by preventing the admission of air to every side of the burning fuel.

That the chews shipped on the river Forth are greatly mixed with culm, is a just and universal complaint of the buyers, and therefore it ought to be taken out by a riddle before they be used; and if chews were so cleaned, they are as fit for rapid distillation as any other coals whatever.

In the mixed coal system, all the culm is separated before the coals are sent to market, by which means there is very little culm produced, even after delivering the coals from the ship; as not a single particle enters into the cart or waggon on the hill. Therefore, from all that has been stated, it must, it is presumed, appear to every impartial mind, that the introduction of the west country system of mixed coal, Would be for the benefit of every individual concerned in the coal-trade, from the coalmaster to the consumer, independently of the advantages attending the plan in a national point of view. All the coalmasters with whom we have conversed upon this subject, confess the injury sustained by the Forth system; but they all consider, that the prejudice is unconquerable, arising more from the habits of the servants than from those who pay for the coals.

But such is the effect of long habit and deep-rooted prejudice, that, in all probability, the predilection for great coal will continue, in spite of evidence and conviction, till firm measures are taken to bring about a reform.

The strength of prejudice cannot be better illustrated, than by an anecdote told by a late eminent and worthy Professor of the Edinburgh University.

He was connected with a colliery, where there was a water-wheel for draining the mines. It revolved with amazing rapidity; and upon this velocity, the mill-wright who took charge of the machine, rested his skill as a mechanic. The Professor, who viewed this velocity with a different eye, ordered pumps of larger dimensions to be attached, which very much reduced the velocity of the wheel, but in a given time, more water was brought up than before. Of this the mill-wright was half convinced. The Professor, still seeing that larger pumps, and a slower motion, would be an improvement, ordered a second alteration. The mill-wright was no longer, an obedient servant he said that he could not think of doing this; for it vexed his heart to see his wheel moving so very slow already, in comparison of its former speed!

Servants who have been accustomed to exert their strength every morning in breaking great coal to pieces, may be told, and half convinced of the superiority of the mixed coal; but the idea they have formed of the superiority of great coal, will, in their minds, (like the quick-running wheel, in the mind of the mill-wright,) always have the preference.

CHAP. V. - The importance of the Coal Mines to Great Britain, considered in a National and Political point of View.

The coal mines of Great Britain, considered in a national and political point of view, are of the first-rate importance; they are indeed one of the vital principles of the State, and every patriotic statesman, and lover of his country, will regard them in this light, whether they be considered as the means of giving bread, and the comforts of life to thousands and ten thousands of inhabitants, or of training a numerous race of the most hardy and intrepid sailors to guard our shores, and protect our liberties and dearest rights.

Valuable as are our mines of iron, copper, tin, and lead, they shrink in comparison with those of coal; for without coal, few of the others could be worked to any advantage, and all our manufactories depend almost immediately on this very useful article. The fostering care of Government ought therefore to be directed to so important a concern, and every privilege allowed, which would tend in any manner to keep the price of coals at a fair and equal rate with other articles.

The iron trade of Britain, which has within these few years attained an astonishing height, depends entirely on coal; and the quality of our iron has been improved so much of late, that there is now no doubt, but that in a few years, we shall not be under the necessity of depending upon a foreign power for a single ton of this most precious and useful metal, and at this critical moment, we feel, as a nation, the high advantage by the progress we have already made in this manufacture. Lately, British iron was only used for the coarsest work; it is now in general use, in demand for our Navy, and its quality is improving every day.

Without coal, the steam-engine, that indefatigable servant, would have been an useless invention to Britain, and without the steam-engine, in what state would our mines and manufactories have been? In short, it is by our coal-mines and steam-engines, that our manufactories have made such rapid progress, and at this moment stand unrivalled, even although the price of labour has been doubled within these twelve years, as before taken notice of. The great scarcity of wood in Britain prevents its being used as fuel. We therefore depend entirely on coal; and as it has now become a very expensive article in the North of Scotland, Ireland, and in many parts of England, every uncommon advance upon the price, must not only be considered as operating against individuals, but against the body politic. Therefore, every plan which can in any degree tend to increase the annual output of the collieries, ought to be most carefully attended to.

From what has been stated with regard to the two modes of working at Glasgow, and on the river Forth, it is evident, that the Glasgow coalmasters work their coal in the way which is most beneficial for themselves, the colliers, the consumer, and the State ; because all the coal is brought to use, and that with the fewest workmen, and therefore the Glasgow system ought to be followed as the best, by every coalmaster. By the awkward plan pursued on the river Forth, the case is most completely reversed in all points. The loss occasioned to the coalmaster, collier and consumer, has already been stated: the loss to the State is this; a greater number of men is required to produce the same quantity of coals; this augments the price, and from the predilection for great coal, immense quantities of lime-coal and culm are left behind in the workings or waste of the pits, and lost to all generations. In many collieries, the quantity of this kind of coal is so great, that a set of workmen are kept below ground for the sole purpose of clearing it out of the colliers' way, where it appears to occupy half of the excavation made by the working of the great coal.

To shew the great proportion which this small coal and the pillars actually bear to the coal brought to the market in the Forth trade, it may be stated, that in a coal-field, the solid pillars of coal which must of necessity be for ever left behind for the support of the roof and safety of the colliers, amount to a third of the whole field; and in general, the small coal thrown aside, is in the proportion of a fifth or a fourth of the coal brought to market, as before stated; that is, the pillars and coal left behind constitute about seven-fifteenths of the whole coal-field. And, as this small coal is fit for the burning of lime, making of salt, or for fire-engines, the leaving of it behind must be looked upon as a loss to the nation. And, without entering into a minute investigation of the matter, it is estimated, that at least sixty thousand tons of this coal are lost annually in the collieries on and adjoining the river Forth, which is equal to the annual output of any one of the largest collieries in Scotland. The adopting of the Glasgow system, formerly mentioned, would rectify this great abuse, and at once bring to market every bit of coal above the size of an inch, for our houses and manufactories, while the smaller coal and dross would serve the purposes before stated. This alone would greatly increase the annual quantity of coal raised at every colliery; and, as the annual quantity increases, the prices must keep in some proportion to it, and afford a more ready supply to those districts of our country where the scarcity of fuel, and the exorbitant prices, are most serious evils, and a complete bar to any great improvement, either in agriculture or in manufactures.

CHAP. VI. - Limited number of Colliers in Scotland considered. - Their numbers cannot be increased, as in other Trades. - Investigation of the Cause. - Loss sustained by the State, when Colliers become Soldiers or common Labourers. - Value of a Colliers Work in an agricultural point of view.

Another cause, which tends to advance the price of coals in Scotland, is, that the number of colliers is very limited. This class of men, from their peculiar habits, form a distinct society, living in houses together at a distance from towns, intermingling very little with the other classes of the community, and generally marrying among themselves, particularly where women are employed to carry coals, as none but a collier's daughter would choose to be a collier's wife in such a case.

All the colliers in Scotland were under a most severe servitude prior to the year 1775. They were accounted ascripti glebae; that is, they belonged to the estate or colliery where they were born and continued to work, and from it neither they nor their children could remove; so much so, that when an estate with a colliery came to be sold, the colliers and their families formed part of the inventory or livestock, and were valued as such; in short, they were bought and sold as slaves. This system secured, indeed, a race of colliers, but it was disgraceful to a free Government, and therefore every man must rejoice at their emancipation.

Before their freedom was granted, it was generally conceived that it was this slavery which prevented common labourers becoming colliers, and it was expected, that, upon removing this obstacle, great numbers of workmen would go to the coal-wall, as the wages were double of what they usually earned above ground. The result has been far otherwise; for, even the allurement of double wages has induced few, very few indeed, to forego the busy haunts of men, and cheerful light of the sun, for the damp, gloomy and dangerous region of a coal-pit. Besides it appears that in working the Scotch coal, which is very strong in the wall, it requires such constant exertion and twisting of the body, that, unless a person have been habituated to it from his earliest years, he cannot submit to the operation. For instance, it is a common practice for a collier, when making a horizontal cut in that part of the coal which is upon a level with his feet, to sit down and place his right shoulder upon the inside of his right knee; in this posture he will work long, and with good effect. At other times, he works sitting with his body half inclined to the one side, or stretched out at his whole length, in seams of coal not thirty inches thick.

It is therefore certain, that the number of colliers cannot be increased at pleasure, as can be done with mechanics and labourers j the latter can begin any time, when young, and from any class of society; but he who is to be a Scotch collier, must begin his labour as soon as he is able to creep to the coal-pit.

Many of the colliers have of late, particularly within these eight years past, betaken themselves to the work of common labourers, at half their original wages. Many of them have enlisted with the army, and not a few have been drawn as militiamen. A collier, therefore, from what has been stated, may be looked upon in one view as a very bad soldier, and most assuredly so, as concerning the policy of the State; for his part, he fights a much better battle for his country when driving vigorously at the coal-wall, than when charging the enemy sword in hand; that is, by his increasing the annual quantity of coal, the price of it is kept moderate, or it only increases in a fair ratio with other articles,— thus extending our manufactures, and spreading the advantages of improved agriculture. But if, by enlistments, and ballots for the militia, one man in thirty be taken, then most certainly the annual output of coal must in proportion be diminished, and hence a national loss be sustained.

To shew the value of a single collier's work, in an agricultural point of view, his annual produce may be estimated at 400 tons.

This quantity of coal would burn of limestone - 2400 tons.

This quantity of limestone would produce of shells - 7200 bolls.

This quantity of shells would produce of slaked lime at least 14,400 bolls.

If 100 bolls of lime be allowed for a Scotch acre, the above quantity would serve as a manure for - 144 acres.

If lime be applied once in seven years, as is the common practice, the quantity of land which could be properly kept in an improved cultivation by one collier, amounts to - 1008 acres.

As at the collieries of Whitehaven and Newcastle, a collier will put out 1200 tons of coals per annum, the number of acres he could keep in cultivation with lime amounts to no less than 3000 acres.

Hence most evidently appears the loss which the State sustains by each collier who leaves his occupation, and becomes either a soldier or common labourer.

From what has been stated, would it not be sound policy to exempt all those who are effective colliers from the militia? Let them be ballotted to prevent subterfuge; but if it can be certified, that they have worked as colliers for five or six years previous to the ballot, let them be exempted from serving, under this certification, however, that upon their leaving the coal-wall, the privilege shall instantly cease. This boon would be in favour of the State, as it would be a strong inducement to the collier to remain at the coal-wall, and thereby prevent many from becoming common labourers.

No doubt the argument which will arise against this will be:—Let the coalmasters protect their men, and secure their services. This protection has been offered to many of them, and they have refused it, because one of their well-known inherent propensities is love of change. Some have accepted of their master's offer, and considerable sums have been paid on this account to provide substitutes, which expence must, if possible, be laid upon the price of coals.

Viewing this matter impartially, there is no doubt but that this privilege would have a very strong effect, provided the principles were most faithfully and honourably acted upon: and the privilege ought to extend to all colliers in the kingdom. . It is a singular fact, that though, as above stated, a very few solitary instances occur of labourers or mechanics becoming colliers, we find great numbers of them employed at all the other works about a colliery, such as making roads below ground, filling coals at the pit bottom, driving mines in the rock, working ironstone, and sinking pits; the last of which is one of the most laborious, wet, and dangerous employments that can be imagined, particularly the sinking of engine-pits, where the smoke of the gun-powder prevents the rays of light from penetrating; so that the workmen are enveloped in the most terrible darkness, where the glimmering light of a candle only extends a few inches, and just serves to shew how impenetrable the darkness is. While employed at this work, there is nothing to be heard but the clanking and rebounding of machinery, the impetuous rushing of water, and the re-echoing sound of the ponderous hammer, while every other hour they have to lay a train to gun-powder ; and quickly springing to the basket, are drawn up the pit by the aid of machinery, with great velocity to escape being blown to pieces; and, it frequently happens, that the train takes fire ere they have ascended a few fathoms; so that the splinters of stones fly around them in all directions; and the sound of the explosion is so overpowering, as to make the ears tingle, and suspend the sense of hearing for some minutes; yet in the midst of these hairbreadth escapes, they go on with their work in the most persevering style. We have seen manufacturers and tradesmen betake themselves to this rough employment, and turn out very excellent, bold and intrepid workmen. But if a proposal were made to these men to change this very dangerous employment for that of a collier, they would spurn the idea even with double wages, and be not a little astonished how such a proposal could be made to them. Can the necessity of early habit, in training a collier, be placed in a stronger point of View, and is it not an argument for the measure proposed, to secure their services?