The Rise And Progress Of Coatbridge And Surrounding Neighbourhood.

Andrew Miller, Dundyvan Iron Works, Glasgow 1864

CHAPTER IX.

The years 1844 and 1845 were characterised by a brisk demand in the iron trade; and, as at such periods, workmen's wages are generally good, this data is taken to show the great amount of capital required for wages, and therefore more or less circulated in the district, from both iron works and collieries around. The examples are only a few, and the data 1844, or for stated periods during its course. At Summerlee Iron Works for that year, the sum paid for wages was nearly £11,800, of which about £6,000 was advanced to the workmen between the regular pay days. At Dundyvan Iron Works, for the same period, the sum paid for wages was not less than £75,000, exclusive of sums paid to contractors at a distance. Nearly £15,200 of the above was advanced to the workmen between the regular pay days. At Gartsherrie Iron Works the sum of nearly £4,800 was advanced between the regular pay days to the workmen during the course of four months of that year. At Drumpeller Colliery, then leased by Mr Buchanan of Mount Vernon, the sum paid for wages for six months was about £5,300, nearly £3,200 of which was advanced to the workmen between the regular pay days. A few more instances could be given, but the above may be considered sufficient to show the continual influx of money to the district, and the immense floating capital required for wages alone; and these are but a tithe of them, the other works and collieries, of course, swelling the amount to an almost fabulous sum, -thus adding prosperity to the district, commerce to our merchants, tradesmen, and others connected in business, and benefiting all.

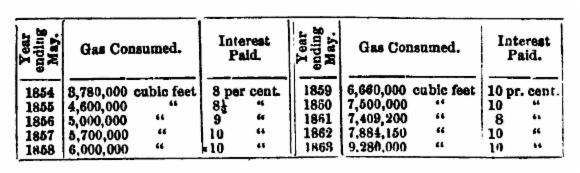

The town of Coatbridge, although surrounded by pillars of fire, and built upon what may be termed the requisite to produce other illuminating powers, could not boast of a gas work till 1843. Previous to this period, however, one house in town appeared to be favoured above all others by a supply of gas from the bowels of the earth. This house belonged to the late Mr James Tennant, merchant and portioner, Main Street. It was the Inn to which travellers resorted to for years, where they could command all the comforts of a home. The peculiar attraction, however, being the blythe, kindly welcome of the late Mrs Tennant, whose ever ready and obliging disposition made her a universal favourite with old and young. The house was not very large, yet it was the general resort for Masonic meetings and other societies, also, dancing schools, concerts, and other entertainments. Each apartment was illuminated with nature's own gas, the supply for which existed for several years. The origin of this mysterious light was rather curious. A few months previous to its discovery, the Messrs Baird of Gartsherrie got permission to put down a bore at the back of the house, so as to ascertain the position or depth of certain metals, and sometime after strange noises were heard to proceed from the hole which was covered over with wood, and one Sabbath evening the sound became so loud, that Mr Tennant's son, Robert, went to make a close inspection with a light. On approaching the place he was suddenly enveloped in flame, which rose to a height of several feet. This flame had a bluish tinge, and much the same appearance as that produced by spirits when ignited. The inspector, however, had presence of mind to throw a wet sack over the place, and thus extinguishing the mysterious fire. The news of the phenomenon spread rapidly, and hundreds of people during the week visited the place to gratify their curiosity. Meanwhile preparations were made and soon completed for fitting, up a purifier and receiver, from which the gas was conducted by pipes into the house, arid for three years the supply from this subterranean manufactory kept twenty-six burners constantly going, as they were required. Many scientific gentlemen from the cities of Glasgow and Edinburgh, and other towns at a distance, visited the scene, to examine the quality and properties of this wonderful gas. Unfortunately, a pit which was sunk at the east end of the town appeared to have struck on the source of the spontaneous combustion, as shortly after, the supply decreased, and gradually became weaker until it nearly ceased. By this time, 1844, the Gas Light Co.'s Works were in active operation, and candles and oil lamps had disappeared in a great measure from shops and dwelling houses. This improvement was the work of a few spirited influential gentlemen in the town, who, in discussing affairs about the latter part of 1842. resolved, at one of their meetings to have "more light," and, after due deliberation, a prospectus for a gas work was issued, and ere many weeks a company was formed, the capital stock being 1333 shares at £3 each. The shares sold rapidly, the works were started, and in 1843 completed so far. The price of this useful light for nearly ten years was 8s 6d per 1000 cubic feet, but the gradual extension of the pipes to four of the large iron works, together with extensions in the town, increased the consumpt to such an extent as enabled the company in 1853 to reduce the price per 1000 cubic feet to 6s 3d; in 1854, to 5s 10d; in 1860, to 5s ; and in 1861, to 4s 7d. In 1858, in consequence of additions and extensions, 333 new shares were issued to meet the expenditure. This additional stock represented the full amount allowed by the deed of copartnery, viz., £5000, but in 1862, general powers were granted by the shareholders to the directors to create new stock to the amount of £1500, for the purpose of laying new branch pipes to the villages of Whiflat, Rosehall, and Calder Iron Works. The inhabitants of these places had the pleasure of enjoying the new light at the close of last year. Like almost every other speculation in the district, these works, by judicious care and management, have proved a profitable investment to the shareholders. Prior to 1854, the average return for capital invested was 5 per cent., since that period, the following table of returns is ample proof of its success. It may be here mentioned that as the copartnery is for twenty-one years, the time will have elapsed in the course of another year, and a new deed of copartnery will therefore be required. As a proof of the stability of the Company, shares are very seldom in the market. When such is the case, they average from £4 10s to £5.

Manager, George R. Hislop, Secretary, Alex. M'Laren, Treasurer, Thomas Torrance, Royal Bank.

The village of Baillieston, situated about three miles west from Coatbridge, is a thriving place, surrounded by extensive collieries. A few enterprising gentlemen connected with the district, in the latter part of 1862, formed themselves into a company, for the purpose of erecting a gas work, to supply the community with this essential element. Operations were immediately commenced, and by the beginning of 1863, the village was illuminated by a supply of gas from these works, which are built on the south side of the turnpike road, and to the east of the toll-bar. The cost of the works, pipes, &c., amounted to upwards of £1400, which was subscribed for by the company in shares of £1 each. The price of the manufactured article is at present 8s 6d per 1000 cubic feet.

The village is rapidly extending, and a handsome County Police Office has been recently erected to the west of the gas work, with ample accommodation both for constabulary and prisoners.

CHAPTER X.

The introduction of gas into the town was a step in the right direction; but another element was still awanting, for as the population increased they suffered severely from the want of a proper supply of water. Their principal dependence for this essential element to cleanliness and health existed in the precarious supplies from a few wells in the neighbourhood, several of which during the drought of summer failed in their supplies. There were two or three wells, however, where the supply was filtered into them from the Monkland Canal, and at such seasons of scarcity the people flocked to these from all quarters, where the scenes were often amusing - women and girls, men and boys, all collected in a promiscuous crowd, waiting for hours, with their receptacles of every shape, colour, and dimension, and ranged in the order of their arrival to get a supply of the precious fluid. The slightest deviation from this rule was sure to result in a general scrimmage, in which the vessels of wood, tin, and stoneware were made to play a very important part over the heads and shoulders of the combatants. Good water was a rarity, and prized accordingly. About a mile to the west, there was a famous well at Dumbank, which was overshadowed by the trees of the Drumpeller woods, and its waters gushed forth in pure crystal streams into a stone trough built into the wall-side that skirts the Edinburgh and Glasgow Road. From it the weary traveller got a refreshing draught, and even the spirit-dealers patronised it, as it made an excellent mixture in reducing the strength and augmenting their stock; but now the water that supplied the fountain has ceased to flow ; the basin is there, green-moulded for want of the usual supply, mocking the passers by; its source has gone into some other channel or pit-working, and the famed water is now only a remembrance of the past. There is also a spring well near the U.P. Church, which still retains its flow. The source of its supply is from a deep sand-bank ; and when a great scarcity prevailed, the minister's water was often in demand, when it could be obtained, for the pump was secured by padlock and key. Water in those days, such as could be used by human beings, was often at a premium, and during the few days annually when the canal was run out (which is invariably in the summer) to work repairs on the embankments, &c., there prevailed a famine for water, and the inhabitants were compelled to extremes, and use the dirty, muddy stuff left in the pools at the bottom of the canal, Which was enough to bring disease and pestilence into the town. To rectify this evil, not only for the populous district of Coatbridge, but also for that of the town of Airdrie, where (in the latter), we have seen the water carted regularly through the town, and sold at a "bawbee the gang," an Act of Parliament was got by a company in 1846 for the construction of waterworks, under the title of the Airdrie and Coatbridge Water Company Act, 9 and 10 Vic., session 1846, to which the Royal assent was given on 27th July of that year. The Waterworks are situated at Roughrigg, in the parish of Shotts - an eligible site, from its high elevation. The reservoir covers about 200 acres, the whole having been constructed under the superintendence of the late Daniel W. Kane, engineer at that time to the Glasgow Water Company. At first, there was only one filter, a very large one, which ultimately proved inadequate to the wants of the consumers, and consequently other two filters were added, under the supervision of Mr William Gale, engineer to the Gorbals Water Company. The undertaking was very expensive, and the cost of works, pipes, &c., connected therewith, went beyond the amount of capital subscribed (4040 shares). The sum expended may be set down in round numbers at £28,737, being £7,500 more than the capital. The original price of shares was £5 each. After the works came into operation in 1848, the water, from some defect at the fountain head, was very impure; and until the evil was remedied, a proportion of the consumers objected to pay for it, which was a serious loss to the company, and for the first four years the revenue could only meet working expenses. In 1853 the shareholders received their first dividend on the capital invested, at the rate of 2 per cent.; in 1854, 2 1/2 per cent.; in 1855, 3 per cent; in 1856, 3 1/2 per cent.; in 1857-58, 4 per cent.; in 1859, 4 1/2 per cent.; and for the last four years it has been 5 per cent. For several years past the supply of water and the quality is all that could be desired, and the resources are abundant. One thing is certain, that the introduction of water by the company was one of the greatest boons ever bestowed upon a community, and, in a sanitary point of view, highly beneficial. The number of consumers in the district of Coatbridge, including those at the Dundyvan, Gartsherrie, Summerlee, and Langloan Works, who are rated as householders, are about 2600, being more than half of the total number (5081), rated for in the Co.'s survey of consumers - according to the returns of 1863.

CHAPTER XI.

It has been said that "coming events cast their shadows before." In this respect Coatbridge for several years had the shadow of civic dignitaries, and consequently an annual election of Provost, Magistrates, and other officials. The Council meetings were held in the "Inn," where the affairs of town and state were duly discussed in regular form, and with a convivial spirit worthy of the realities of an actual burgh. The members of Council had no special night of meeting, but they met very frequently, for the mirth and jollity that prevailed was very attractive, so that, with a few exceptions, the attendance was regular. The fines exacted for non-attendance went to the general fund, so that all tended to harmonise and qualify each member for the duties of office, and was sufficient inducement to prolong the Council meetings or to adjourn. Strangers were considered highly favoured when admitted. This jolly Council was carried on for years, still the coming event of which this was the shadow has not yet come; and Coatbridge, although entitled from its population and position to rank as a burgh, and has gentlemen of ability connected with it, who ought to be entrusted to govern its affairs, is still, from want of spirit or something else, as it was, and it is neither a burgh on the roll Parliamentary nor Royal. As an example of how business could once be done in former years, the election for 1845, as issued officially for that year, is herewith given:-

List of the Magistrates, Town Councillors, and Officials of Coatbridge, Elected November, 1845.

William Miller, Esq., Provost

Robert Russell, Esq. Baillie

Thomas Fell, Esq., Baillie

James Walker, Esq., Baillie

Councillors

Robert Douglas

William Waddell, jun.

Matthew Fairlie

William Hill

David Crichton

James Jamieson

James Tennant, jun.

Adam Clark

William Boyd

John Lumsden

Andrew Ramsay, Treasurer

John M'Lachlan, Fiscal.

Robert Swan, Town Clerk.

Official Appointments

Malcolm Miller, Deacon Convener.

William Thomson, Dean of Guild.

James Miller, Chamberlain.

James Gordon, Inspector of Buildings.

William Waddell, Master of Works.

Isaiah Clark, Civil Engineer.

William Morrison Water Baillie.

James Tennant, sen., Inspector of Weights and Measures.

James Taylor, Foreign Correspondent.

John Cairns, Inspector of Streets.

Robert Prentice, Railway Inspector.

James Currie, Town Officer.

Note - In 1846 another official was added to the list, a wee laird in town (now deceased,) having been displeased at not receiving an appointment among the officials. The following year his name appeared with the questionable title attached, "Finisher of the law."

As this election went the rounds of the Glasgow press as from a bona fide burgh, it was taken for granted that such existed; and not long afterwards, a minister from the west of Scotland, having occasion to officiate in the Gartsherrie Church, the congregation was both astonished and no doubt not a little amused to hear the rev. gentleman's special prayer for the Provost, Magistrates, and Town Council of Coatbridge. The worthy man had taken it for granted that such officials did exist, and was very much surprised when enlightened on the subject.

For many years after the iron works started, the town was often the scene of drunken brawls, over which the mock civic dignitaries appeared to have no control. On such occasions it was often dangerous for the more peaceful inhabitants to venture out in the streets at night, and the whole district became so notorious for rowdies and scientific pugilism that the merchants got. alarmed, and for some time employed and paid a night watchman for the protection of their property. This state of matters continued till 1846, when a regular police force was organised, the Act for which was obtained in the month of September, and was entitled "An Act to erect and constitute the parishes of Old and New Monklands, and parts of the parishes of Bothwell and Shotts, into one police district, for the establishment of an efficient police force therein, and for other purposes relating thereto'' to which the Royal assent was given 18th June, 1846. The establishment of such a force was of great importance, and the results were equally satisfactory. Improvements followed, and in 1855 another Act of Parliament was obtained for the combined rural districts of Airdrie and Coatbridge. This second Act was obtained in the session of 1854-5, and was entitled "An Act to repeal the former one; to reconstitute and extend the police district therein mentioned, under the name of the 'Airdrie Rural Police District;' and to erect and maintain a hall, courthouses, and public offices, for the Airdrie and Coatbridge district of Lanarkshire," to which the Royal assent was given 30th July, 1855. This Act continued in force till 1858, when, in March of that year, the police merged into the county force of constabulary, under Chief Captain Mackay - Superintendent, Thomas Clarke for the district of Coatbridge and Airdrie. Inspector for Coatbridge, Mr Peter Stewart.

CHAPTER XII.

Let us now proceed to notice in detail the erection of the respective manufactories in the district. The Caledonian Tube Works, established in 1844, by the late William Baker, the first work of this description in Scotland, for the manufacture of the patent lap welded iron tubes for steam boilers. The patent expired in 1857. The tubes so produced are exported to nearly every quarter of the globe. The number of men employed average from 30 to 80 according to the demand; and the works are now carried on by Joseph Baker, Esq., Woodside House.

The Atlas Foundry, established in 1845, by the present proprietors, Messrs James M'Gilchrist & Co. In addition to the production of Cast Iron Work, a large business is carried on in the engineering department.

The Britannia Tube Works, erected in 1851, by John Lumsden & Co., where iron tubes for blast furnace twyeers, shovels, spades and brass castings are produced. ,This work employs, on an average, about 30 men and boys.

The Maryston Iron Works, established in 1851, are now carried on by Messrs Hugh Martin & Sons. At these works there are six puddling and two heating furnaces, with engines and other machinery, capable of producing about 300 tons of finished malleable iron monthly.

Coats Iron Works, erected in 1854, by the late Thomas Jackson, Esq., of Coats, at which there are twelve puddling and two heating furnaces, with the necessary machinery, capable of producing nearly 600 tons of finished malleable iron monthly. In addition to these works a neat and substantial structure was erected close adjoining, in 1861, for the manufacture of lap welded iron tubes, with all the requisite machinery. The tube work was leased to Messrs Andrew Stewart & Co., of Glasgow, in the latter part of last year, who are carrying on the work very successfully in all its branches. The total cost of the whole works as at present in operation, is said to have been upwards of £10,000. The Malleable Works are now carried on by Captain Jackson, of Coats. (At several of these Malleable Works extensions have been made lately, which have increased their power of produce in this branch of manufacture.)

Drumpeller Iron Works, erected in 1859, by Messrs Henderson and Dimmack. At these works there are twelve puddling and three heating furnaces, with the necessary machinery, capable of producing about 600 tons of finished iron monthly.

The Phoenix Iron Works, erected in 1861, and now carried on by Mr James Spencer, have six puddling and two heating furnaces, with engines and machinery capable of producing 250 tons of finished iron monthly.

The Clifton Iron Works, also erected in 1861, by Messrs Colville & Gray, at which operations in the manufacture of iron were commenced in February, 1862. At these works there are ten puddling, and three heating furnaces, with all the appliances of machinery, capable of producing about 600 tons of finished malleable iron per month. The total cost of these works was upwards of £7000.

Coatbridge Works (lately Munroe's Foundry), now the property of Messrs Begg & Wilson, who carry on an extensive manufacture of iron tubes, pipes, shovels, spades, &c., and also the business of brass-moulders, the whole giving employment to upwards of 30 men and boys.

North British Iron Works. These works were originally known as Ronald's Forge. The latter, when first erected in 1840, and for many years afterwards, belonged to Mr Ronald, who carried on the manufacture of axles, wheel tyres, &c., and other forgings. After it was converted into a malleable iron work, it was known as the "Phoenix," but the present lessees, Messrs Ellice and Mackenzie, changed the name to the North British. It is a very compact little work, with two puddling and two heating furnaces, along with machinery capable of turning out 150 tons of finished iron per month.

All the foregoing are situated in the immediate vicinity of the town, and have been the means of augmenting the population, and adding to the general prosperity. A manufactory for steel springs, &c., in 1860, was erected near the Drumpeller Iron Works, but after a few months' trial it was given up. The whole of these works, viz.:- Atlas Foundry, North British, Caledonia, Britannia, Clifton, Phoenix and Coats, are built on the Coats' estate, on the north side, and along the bank of the Monkland Canal. A branch off the Monkland Railway runs along the side of the Canal, thus giving every facility by land and water, for the transit of materials to, or merchandise from the respective works.

Coatbridge Tin Plate Works. These works, which are situated on one of the most eligible sites in the district, on the estate of Whifflat, at the Laigh Coats, were started at the latter end of the present year. They are the only works of the same description in Scotland, and the proprietors (Messrs Baillie and Bell) deserve credit for their enterprising spirit in thus adding another branch to our iron manufacture, which, it is calculated, will give employment to about seventy individuals. The works are built on the most approved principles - the machinery and fittings are of the best description, with all modern improvements. There are two puddling furnaces, two lumping furnaces, a hollow fire, a softening fire, with arrange of tinning pots, a couple of engines to propel the rolls, a Condie hammer, and every other appliance necessary for manufacturing the iron through all the various stages from puddling, hammering, rolling, re-heating, cutting, softening, pickling, and lastly, tinning, when it is finally packed in boxes, in quantities of 3/4 to 1 cwt. in weight, ready for the market. The estimated produce of such a work is about 500 boxes per week. In the tinning process, females are employed, so that this is a new phase in iron manufacture in the district. The works are advantageously placed for carriage of the raw material or produce either by railway or canal, and with its energetic proprietors, there can scarcely be a doubt as to its future prosperity.

Tennant's Foundry is situated at the bottom of Buchanan Street. The enterprising lessee, Mr Robert Tennant, has recently expended upwards of £1000 in extending and re-building the same, in order to enable him to meet the demand for heavier castings in machinery and other goods of a like description. This foundry was formerly known as Smellie's engineering establishment. There are also several extensive woodyards in the town, which have saw mills attached. The respective proprietors are Mr William Waddel, Messrs Allan & James Waddell, Mr John Hill, and Mr John Murray, who give employment to a considerable number of men, in building houses, railway waggons, bridges, piers, &c. Their enterprising spirit leads them to accept of contracts in these branches in nearly every part of the country, and their career in this respect has hitherto been very successful. At Sunnyside Messrs Tudhope and Gray have erected a bolt and rivet manufactory; these works, when fully started, will be able to produce about ten tons of the manufactured article daily.

The Maryston Works and Drumpeller Works are built on the Drumpeller estate, the former a short distance to the west of the Caledonian Railway Station, near the canal, which is convenient for transit; the latter near to the Langloan Iron Works, with every facility for transit both by railway and canal, as the latter lies close to the west side, and the former runs into the works.

The Rochsolloch Iron Works are situated near the village of Coatdyke, and were erected in 1858, and consist of six puddling and two heating furnaces, capable of producing nearly 200 tons of finished malleable iron monthly.

All the works possess the same advantages of transit for their produce, by the Monkland Canal or Railway, and additional advantages will be derived by the construction of the new line of railway (Glasgow, Baillieston, and Coat-bridge branch) by the Caledonian Company, which is expected to be finished in the course of another year. This railway will form another outlet for the increasing traffic of the district, at the same time it will be of great importance in developing the valuable seams of coal in the west division, and providing supplies of that excellent mineral to the works in this neighbourhood. This branch line of railway is to give accommodation to that portion of the western district extending along the north valley of the river Clyde, and both sides of the Calder water, joining the Caledonian at Coatbridge on the north, and Whifflat on the south, and these two branches forming a junction near the Souterhouse Colliery to the west, and running west, by Drumpeller, Dykehead, Bredisholm, Baillieston, Mount Vernon, Foxley, Tollcross, Clyde, &c., and on to the Dalmarnock branch of the Clydesdale Junction Railway, by which direct communication will be formed with Glasgow, Paisley, and Greenock. The coal fields through which this line passes are very extensive, and several large portions of them are still unwrought, the opening up of which, together with the further development of those working collieries, will add materially to the prosperity of the district. And there is little doubt that as soon as this outlet for minerals and merchandise is finished, it will at once take its place as one of the best feeders on the Caledonian Railway.

The coal required in the manufacture of iron, at the various malleable works, may be set down at upwards of 90,000 tons annually, and by calculating upon those at present in operation to turn out only three-fourths of the iron they are capable of producing, the produce of finished malleable iron would average upwards of 33,000 tons annually. The coal required in the various processes to which the iron is subjected, from its crude state until finally sent to the market as bars, rails, boiler-plates, &c., &c., is generally estimated at from 2 10/20 tons, to 2 15/20 tons, to each ton of finished iron. The above will, therefore, be found to be very near the mark, and by extending the calculations a little further, the 33,000 tons of iron so produced, taking the market price at a fair average over all, the sum represented by this branch of industry may be set down at upwards of £300,000 per annum.